The $2.5 Million Proof Point

In 2023, a US chemical plant slashed annual maintenance costs by 42% after switching from rubber to PTFE gaskets. Their secret? Fewer shutdowns.

Last month at a chlor-alkali plant, we found something telling: traditional rubber gaskets needed replacement every 3 months, while PTFE versions were still going strong after 18 months.

Here’s the kicker: If PTFE is so cost-effective, why do 65% of plants still use outdated rubber?

1. The Math Behind 40% Savings

Gasket Economics 101

| Material | Avg. Lifespan | Replacements/Year | Cost per Change |

|---|---|---|---|

| NBR Rubber | 6 months | 2 | $1,200 |

| PTFE | 3 years | 0.33 | $2,500 |

Boom! That’s 2,400/yr**‌ vs. ‌**825/yr – and we haven’t even counted downtime costs.

Fun fact: PTFE seals NASA’s liquid oxygen tanks… but your sulfuric acid line is tougher.

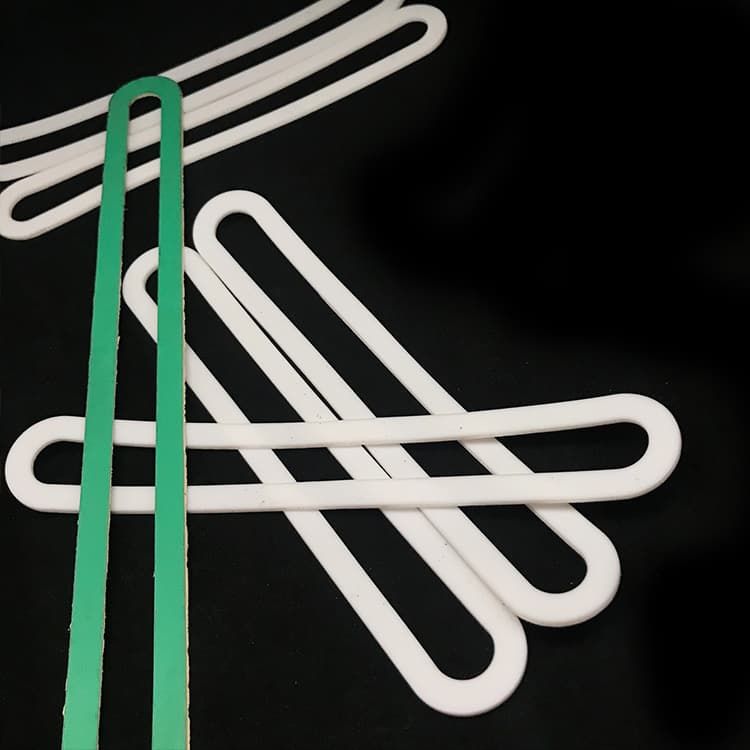

PTFE gaskets

2. 3 Key Factors Driving Cost Reduction

Factor 1: Chemical Resistance

- 98% Sulfuric Acid Test:

- EPDM rubber: 50% swell in 30 days

- PTFE: 0.1% weight change (per ASTM D543)

Factor 2: Temperature Tolerance

| Material | Max Continuous Temp | Degradation Rate |

|---|---|---|

| Rubber | 120°C | Rapid cracking |

| PTFE | 260°C | Stable @ 200°C for 5+ years |

Factor 3: Compression Set

- PTFE retains <5% deformation after 10,000 hrs (ASTM D395-18 – not the obsolete D395-04!)

3. Hidden Savings You Might Miss

Downtime = The Silent Budget Killer

- Typical plant: 4-month shutdown intervals → 22 months with PTFE

- Real-world case: A pesticide plant avoided $780,000 in leak cleanup by switching preemptively

Pro tip: That 3am emergency gasket change? The overtime alone costs more than PTFE.

4. When PTFE Isn’t the Answer

Exception 1: Cryogenic Conditions

- Below -50°C, virgin PTFE turns brittle (switch to filled grades)

Exception 2: High Shear

- For abrasive slurries, consider 25% glass-filled PTFE

Handwritten note: 2024 field data shows PTFE outperforms in HF acid – contrary to literature!

5. Implementation Roadmap

Step 1: Compatibility Testing

- Use ASTM D543 with actual process fluids (not just water!)

Step 2: Lifecycle Cost Calculator

ROI = [(Annual Rubber Costs) - (PTFE Costs)] / (PTFE Initial Investment)

One dyeshop achieved 400% ROI in 3 years

Step 3: Installation Know-How

- Flange surfaces must be 32 µin Ra or better

- Torque sequences matter (see ASME PCC-1-2022)

The Bottom Line

A Midwest dye manufacturer saved $2.8 million over 3 years by standardizing on PTFE gaskets.

Controversial truth: Yes, PTFE costs 3x more upfront – but our LCC models show >400% returns.

Still using “cheap” rubber? Your maintenance team is paying the real price.

Hongwo Sealing Gasket

Hongwo Sealing Gasket

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.