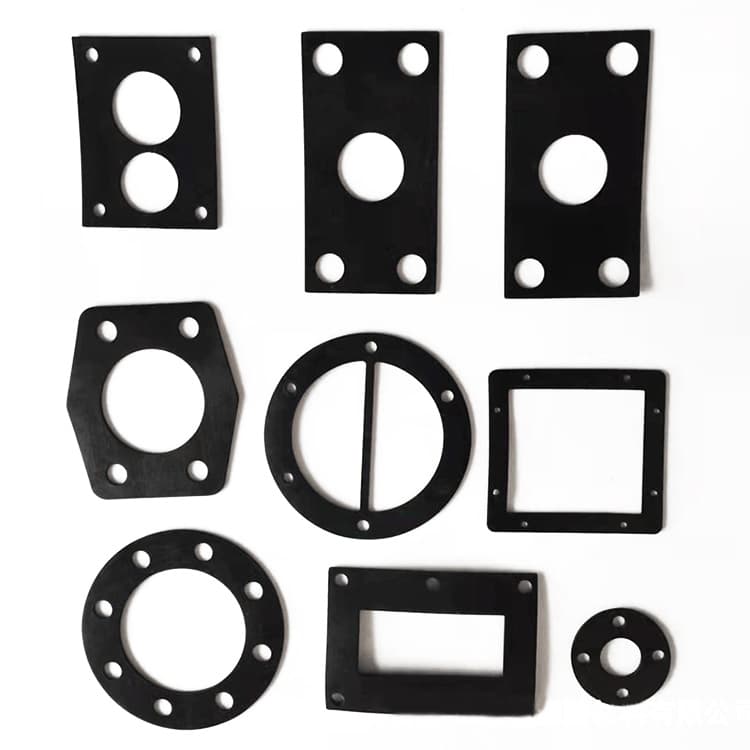

FKM black glange rubber sealing gasket is gaskets used for sealing. The main products include silicone gaskets, nitrile rubber gaskets, etc.

The main rubber sealing gaskets are silicone, nitrile, and fluorocarbon rubber gaskets, and other rubber gaskets.

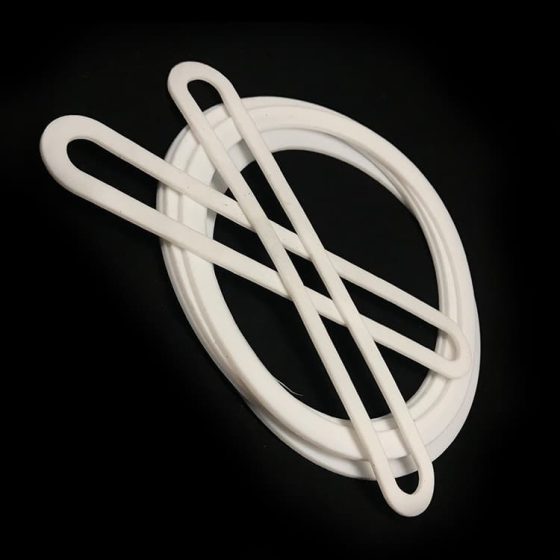

Silicone rubber

It has outstanding high and low temperature resistance. Heat resistant molded cutting seal rubber gasket maintains good elasticity within the temperature range of -70℃ to +260℃. It resists ozone and weathering. So, it is a good sealing gasket for thermal machinery. It is non-toxic. It can make thermal insulation, insulation products, and medical rubber products. Heat resistant molded cutting seal rubber gasket also has excellent properties. They are: water resistance, flame retardancy, high temperature resistance, electrical conductivity, wear resistance, and oil resistance. It is widely used in various industries such as machinery, electronics, and plumbing. Our silicone gaskets meet EU environmental and food-grade standards.

Nitrile rubber

NBR is a polymer formed by emulsion copolymerization of butadiene and acrylonitrile. It is famous for its oil resistance. It also resists wear, aging, and air leaks. Thus, it is widely used in the rubber industry.

Fluorine rubber

It withstands high temperatures, and people can use it in environments ranging from -20℃ to +200℃. It is resistant to strong oxidants, oil, and acid and alkali. People use it in high-temperature, high-vacuum, and high-pressure environments and in oil environments. It is widely used in the petroleum, chemical, aviation, and aerospace industries.

Other characteristics

Chloroprene rubber, natural rubber, EPDM rubber, acrylate rubber, and other special rubber. They are oil, acid, and alkali resistant. They resist wear and high and low temperatures.

Application

Rubber gaskets resist oil, acids, alkalis, heat, cold, and aging. Industries like auto, electronics, chemicals, anti-static, flame retardant, and food use them a lot.

Hongwo Sealing Gasket

Hongwo Sealing Gasket

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.