Flexible Composite Graphite Gasket

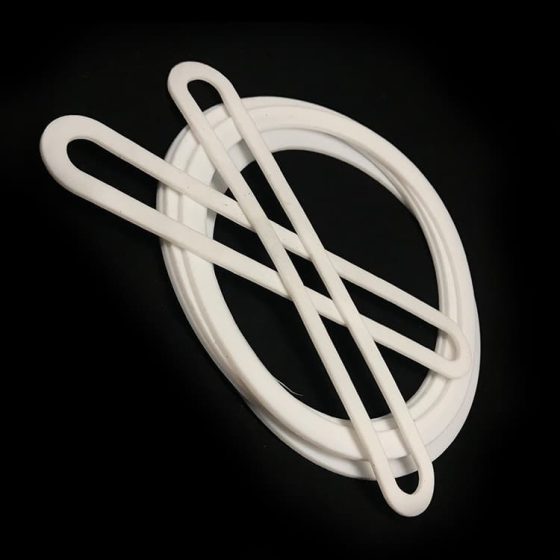

Manufacturers make flexible graphite composite gaskets from reinforced graphite plates. These gaskets are also called reinforced graphite gaskets. They make the plates by punching or cutting. They are also called high-strength graphite gaskets. High-strength flexible composite graphite gaskets resist corrosion and high and low temperatures. They have good compressibility and resilience, and high strength. Reinforced graphite gaskets use inner materials like SS304, SS316, or tinplate. Their thickness is 0.1 to 0.127 mm. The forms include perforated plate reinforcement, mesh plate reinforcement, and flat plate reinforcement. Manufacturers commonly use 304 reinforced graphite to make various circular gaskets. Industries widely use these gaskets in pipelines, valves, pumps, and heat exchangers. They are also used in generators, air compressors, exhaust pipes, and refrigerators. They can also cut graphite reinforced gaskets into complex shapes. These include water level gauge gaskets, perforated flange gaskets, and cylinder gaskets for diesel engines.

Manufacturers can process high-strength graphite gaskets into forms based on usage requirements.

1. Basic-type graphite composite gasket

2. Inner edge-wrapped graphite composite gasket

3. Outer edge-wrapped graphite composite gasket

4. Inner and outer edge-wrapped graphite composite gaskets.

The edge-wrapped graphite composite gaskets keep the original gasket’s high performance. They are easier to install and remove. They are also less prone to damage. The design prevents erosion of the gasket by the medium, improving pressure resistance. Manufacturers frequently use 304 or 316 stainless steel as edge-wrapping materials.

The max size for graphite composite gaskets is 20 to 5,000 mm. We can customize special specs or non-standard products to meet customer needs.

Hongwo Sealing Gasket

Hongwo Sealing Gasket

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.