High-temperature-resistant PTFE gaskets, or Teflon gaskets, are common sealing materials in the industry. Cutting or turning creates PTFE rods, tubes, and plates. This shapes them into flat gaskets, V-gaskets, piston rings, and ball valve gaskets.

Characteristics

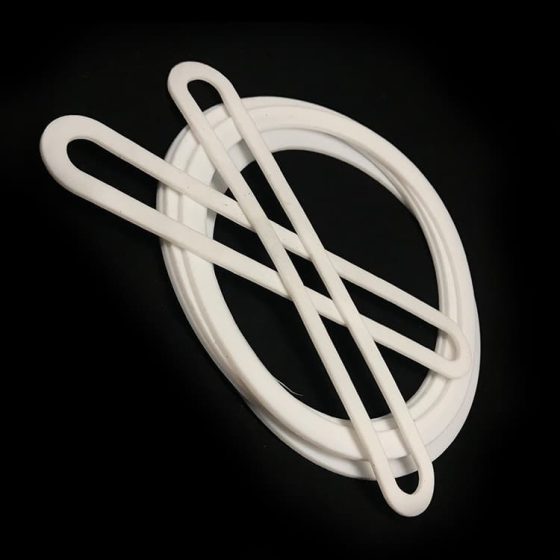

High Temperature Resistant PTFE Flange Gasket

PTFE gaskets resist -100°C to 260°C. They suit high-temp use in pumps, compressors, mixers, and centrifuges in fluid machinery.

Corrosion resistance: They can withstand corrosive media, such as acids, alkalis, and salts. They are ideal for use in chemically corrosive environments.

Non-conductive: They insulate well. They are perfect for situations needing electrical insulation.

Low friction coefficient: They have a low friction coefficient. It can reduce friction and energy use in machines.

Good sealing performance: They can maintain stable sealing effects in various media.

Application fields

PTFE gaskets are widely used in many industrial fields, mainly including:

Chemical and pharmaceutical industries: for sealing various corrosive media.

Oil and gas industries: for sealing in high-temperature and high-pressure environments.

Power and steel industries: for use in high-temperature steam and oil environments.

Fluid machinery, such as pumps, compressors, mixers, and centrifuges.

Processing and handling requirements

PTFE gaskets have high system requirements. They must operate in specific temperatures and environments to ensure stable, long-lasting performance.

Hongwo Sealing Gasket

Hongwo Sealing Gasket

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.