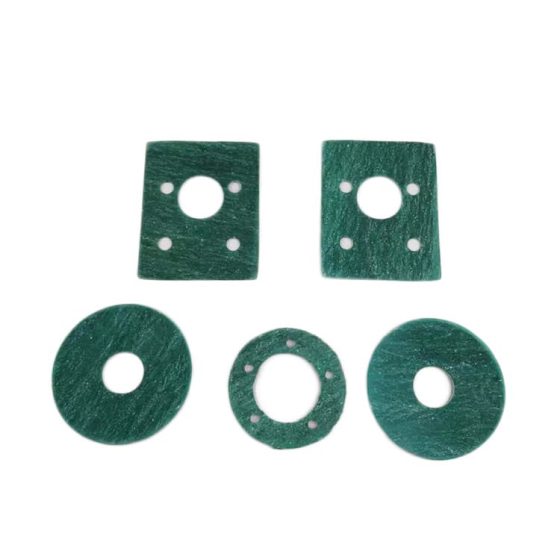

Manufacturers make asbestos gaskets from asbestos fibers and rubber. These are the main raw materials. Rubber compounding agents and fillers also supplement them. The process uses mixing and stirring, hot roller forming, and vulcanization. Experts can classify asbestos fiber gaskets into two types. They are ordinary rubber gaskets and oil-resistant asbestos rubber gaskets. Asbestos Flange Gaskets base this on their formulas, performance, and uses. They can seal water, steam, oil, solvents, and some acids and alkalis. Asbestos Flange Gaskets use them to seal medium and low-pressure flange connections. The most commonly used thicknesses are 3 mm to 5 mm.

Asbestos Flange Gaskets

Applications:

It is for sealing the openings of:

reaction vessels

boiler manholes and hand holes

flue box belts

steam ball seals

It can seal tank openings, manholes, and hand holes.

Many fields use the products. They include chemical engineering, petroleum, electronics, and machinery. Also, they include power and environmental protection. The chemical engineering fields are pharmaceuticals, pesticides, fertilizers, dyes, polymers, and intermediates.

Application range:

Operating temperature: -100°C to +1000°C

Operating pressure: PN < 5.0 MPa

Main technical parameters of asbestos gaskets:

Model: XB200, XB250, XB300, XB350, XB400, XB450;

Tensile strength: 5 MPa, 6 MPa, 8 MPa, 9 MPa, 11 MPa, 18 MPa;

Temperature: +200°C, +250°C, +300°C, +350°C, +400°C, +450°C;

Hongwo Sealing Gasket

Hongwo Sealing Gasket

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.