1. Functional Description

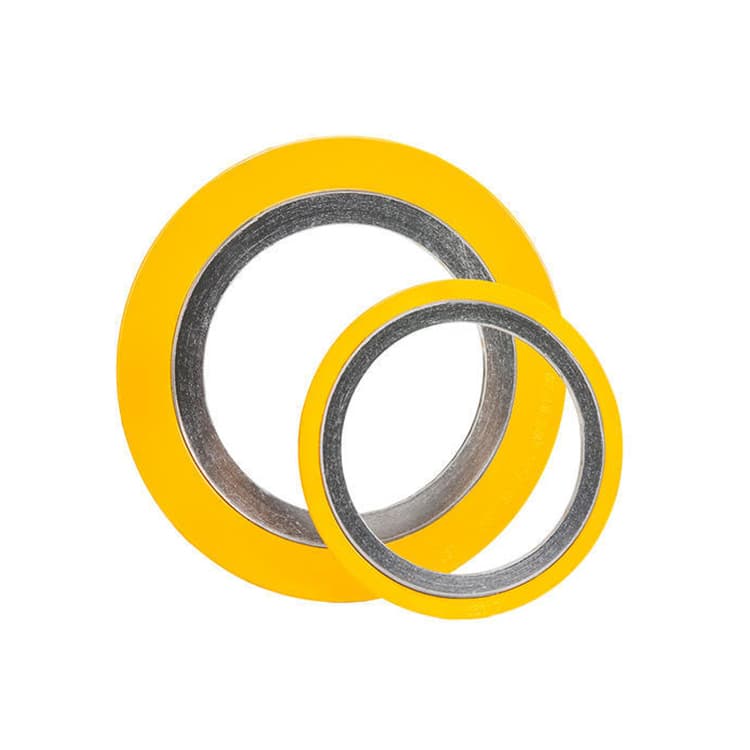

Spiral wound metal gaskets are precision-engineered sealing components designed for extreme industrial environments. They consist of alternating layers of V-shaped metal winding strips (commonly stainless steel 304/316, titanium, or Inconel) and non-metallic filler materials (e.g., flexible graphite, PTFE, or mica) spirally wound under controlled tension. This hybrid structure provides dual sealing mechanisms:

- Metal strips ensure mechanical strength and resilience under thermal cycling.

- Filler materials achieve leak-tight sealing by conforming to flange surface imperfections.

Key performance advantages include:

- Wide temperature range: -200°C to +800°C continuous operation.

- Pressure resistance: Up to 3,000 psi (206 bar) static and dynamic loads.

- Chemical compatibility: Resistant to acids, alkalis, hydrocarbons, and steam.

2. Engineering Data Validation

2.1 Compression-Recovery Testing

Independent lab tests validate a minimum 15% recovery rate after 50% compression (ASTM F586 standards), ensuring long-term sealing integrity under cyclic loads.

2.2 Leakage Rate Certification

- Helium leak rate: ≤1×10⁻⁹ mbar·L/s (EN 13555 Class L0.1).

- Hot tightness: Maintains sealing at 600°C for 500 hours (API 601/6G specifications).

3. Scenario-Based Applications

3.1 Oil & Gas Pipeline Flanges

- Case: Offshore platform gas compression systems (API 6A/6BX flanges).

- Solution: SS316L + PTFE gaskets prevent sour gas (H₂S) corrosion and thermal creep at 450°C/2,200 psi.

3.2 Chemical Reactor Manways

- Case: Polyethylene reactor manway sealing (ASME B16.20 flanges).

- Solution: Inconel 625 + expanded graphite gaskets withstand 98% sulfuric acid exposure at 300°C.

4. Compatibility & Selection Guide

4.1 Material Pairing Matrix

| Metal Strip | Filler | Compatible Media |

|---|---|---|

| SS304 | Flexible Graphite | Steam, hydrocarbons, mild acids |

| Titanium | PTFE | Chlorides, nitric acid, solvents |

| Inconel 625 | Mica | Molten salts, superheated steam |

4.2 Flange Surface Requirements

- Ra ≤ 3.2 μm (ASME B16.5).

- Avoid serrated flanges with spiral wound gaskets; use flat-face or raised-face designs.

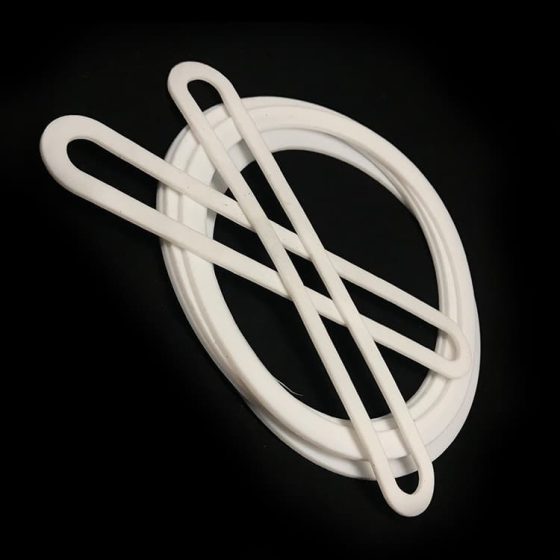

5. Installation Protocol

5.1 Pre-Installation Checks

- Inspect flange surfaces for scratches or pitting (reject if defects exceed 0.05mm depth).

- Clean residual sealant from flange grooves with non-abrasive tools.

5.2 Torque Sequence

- Step 1: Hand-tighten bolts in a star pattern.

- Step 2: Apply 30% final torque, then 60%, and finally 100% in three passes.

- Torque values: Refer to ASME PCC-1 guidelines (e.g., 120 N·m for M24 bolts).

6. Safety Warnings

- DO NOT reuse gaskets after disassembly; plastic deformation compromises sealing.

- Avoid over-compression: Exceeding 50% strain causes filler extrusion and metal strip buckling.

7. Common Installation Errors

7.1 Misalignment

- Error: Installing gaskets with misaligned inner/outer rings.

- Consequence: Uneven stress distribution → flange warpage.

7.2 Incorrect Filler Selection

- Error: Using PTFE filler in >260°C oxygen-rich environments.

- Risk: PTFE decomposition → toxic gas release.

8. Maintenance & Inspection

8.1 Routine Checks

- Thermal imaging: Monitor flange hotspots (>10°C variance indicates leakage).

- Bolt retorquing: Required after 500 operational hours (follow ASME PCC-1).

8.2 Degradation Signs

- Graphite filler: Black powder residue on flange faces.

- Metal strips: Visible cracks or discoloration (indicates oxidation).

Hongwo Sealing Gasket

Hongwo Sealing Gasket

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.