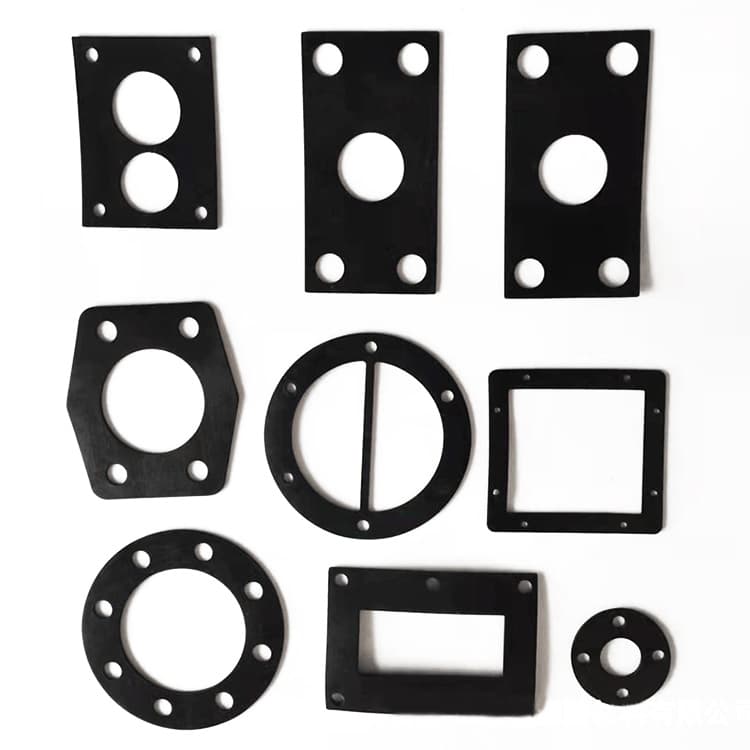

I. Dimensional Specifications

Rubber gaskets must meet product standards and customer specs for dimensions. Regulations must measure diameter, thickness, and length. This ensures they meet the required accuracy and tolerance.

II. Material Requirements

Manufacturers should make rubber gaskets from high-quality, durable rubber. They should be highly elastic. Rubber gaskets must resist corrosion and aging. They also need to endure high and low temperatures. The materials must meet relevant standards and customer requirements. They must include quality and qualification certificates.

III. Physical Properties

1. Hardness: Rubber gaskets must meet product standards and customer specs. Their hardness should be Shore A 40 to 90.

2. Tensile Properties: Rubber gaskets must have certain tensile properties. They need to adapt to changes in pressure and temperature.

3. Compression Set: Rubber gaskets are subject to pressure during use. They need a certain compression set to ensure sealing and a long service life.

4. Tear Strength: Rubber gaskets must have at least some tear strength. This is to ensure their durability during use.

5. Abrasion Resistance: Rubber gaskets must resist friction and wear. So, they should have good abrasion resistance.

IV. Chemical Properties

IV. Chemical Properties

1. Oil Resistance: Rubber gaskets must resist erosion from various oils.

2. Solvent Resistance: Rubber gaskets must resist erosion from chemical solvents.

3. Corrosion Resistance: Rubber gaskets must resist chemical corrosion.

V. Corrosion Resistance

Rubber gaskets must resist corrosion and erosion from acids, alkalis, and salts. They must also resist other chemicals. When selecting materials, consider the usage environment and conditions. This will help you choose suitable rubber materials.

VI. Sealing Performance

Rubber gaskets must seal well. They should prevent gas and liquid leaks. The production process must ensure the gaskets’ size and surface quality. They should use advanced vulcanization methods to improve their sealing performance.

VII. Anti-Aging Performance

Rubber gaskets should resist aging. They must keep their physical and chemical properties during long-term use. When choosing materials, consider the environment and conditions. Select rubber with good anti-aging performance.

VIII. Safety

Rubber gaskets must meet safety standards. They should not harm humans or the environment during use. Use eco-friendly materials and processes in production. This ensures that the products are safe and green.

IX. Environmental Requirements

Rubber gaskets must meet environmental standards. They should use eco-friendly materials and processes. We should recycle discarded gaskets to reduce environmental pollution.

X. Packaging and Marking

Rubber gasket packaging and marking must be clear and complete. They should be easy to identify. The packaging should state the product name, model, manufacturer, and production date. It should also include information to help customers use and maintain the product.

Hongwo Sealing Gasket

Hongwo Sealing Gasket

IV. Chemical Properties

IV. Chemical Properties