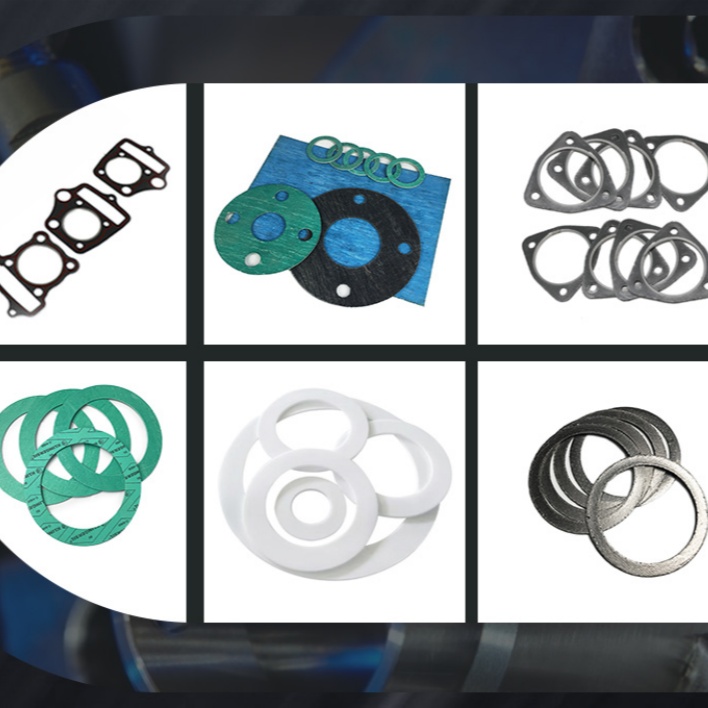

Having worked with extrusion dies for years, I’ve come to appreciate the subtle but critical role gaskets play. Here’s my perspective on their key functions:

1. Fine-Tuning the Gap

sealing gaskets in extrusion dies

In my experience, adjusting the space between the die and extrusion rod is the first step to achieving precision. A slight mismatch here can lead to uneven surfaces or dimensional errors. By swapping out gaskets of varying thicknesses, I’ve managed to dial in tolerances that ensure parts meet exact specifications—no guesswork involved!

2. Balancing Pressure Distribution

Multi-hole dies can be notoriously finicky. Without proper pressure distribution, you’ll end up with defects like warping or inconsistent material flow. I’ve found that strategically placed gaskets act like “equalizers,” spreading force evenly across all openings. This not only smooths production but also cuts down on rework.

3. Sealing Against Leaks

High-pressure extrusion is messy business. Early in my career, I saw how molten metal could seep through even the tiniest gaps, causing safety hazards and die damage. A well-sealed gasket system, though, locks everything in place. It’s like putting a lid on a boiling pot—controlled and contained.

4. Shielding the Die from Wear

Extrusion rods take a beating. Over time, vibrations and impacts can wear down surfaces, leading to costly replacements. I’ve noticed that gaskets act as a shock absorber, soaking up stress before it reaches critical components. Think of them as the die’s personal bodyguard.

5. Streamlining Maintenance

Let’s be honest—no one enjoys dismantling dies. But with gaskets, disassembly becomes almost effortless. I’ve saved hours by using modular gasket setups that simplify alignment during reassembly. Less downtime means more throughput, and who doesn’t want that?

Final Thoughts

Gaskets might seem like small players, but they’re game-changers in extrusion die performance. From my trials (and errors), prioritizing gasket quality and configuration has consistently paid off in smoother operations and longer tool life. Don’t overlook these unsung heroes!

Hongwo Sealing Gasket

Hongwo Sealing Gasket