Gasket sealing is a trusted method. It’s used in many machines and industrial settings. Applying pressure changes the shape of the gasket. It fills gaps between surfaces, forming a strong seal. In practical engineering, engineers know gasket sealing for its simplicity. It’s cost-effective and easy to install or replace. This makes it a popular choice for professionals.

Several key aspects can break down the principle of gasket sealing:

1. Compression Deformation:

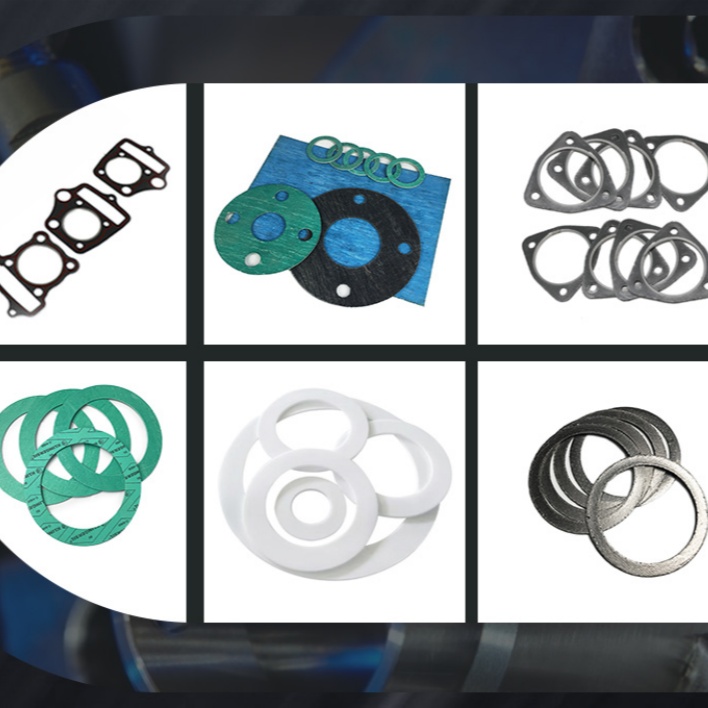

Gasket Sealing

When installing a gasket, it undergoes compression due to applied pressure. This compression makes the gasket change shape a bit. It helps fill small gaps between the surfaces that connect. This deformation is fundamental to achieving a reliable seal.

2. Elastic Recovery Beyond compression, gaskets also have elastic properties. When the external pressure is gone, the gasket goes back to its original shape. This keeps a strong and lasting seal over time. This elasticity contributes to the longevity and reliability of the seal.

3. Material Selection Choosing the right material for your gasket is crucial. Different environments and media need different types of sealing gaskets. These can be metal, non-metal, or rubber. Pick materials that resist pressure, wear, and corrosion. This choice ensures top performance and lasting durability.

4. Surface Treatment

The state of the connecting surfaces is key to how well the seal works.

Proper surface treatment helps improve flatness and smoothness. This includes grinding, polishing, and smoothing. These steps ensure the gasket works at its best.

In summary, gasket sealing uses the gasket’s ability to compress and recover. This creates a strong, reliable seal. Focusing on detail when picking materials and preparing surfaces ensures long-lasting, dependable performance.

Hongwo Sealing Gasket

Hongwo Sealing Gasket

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.